The reason we would to do this is common multi-meters do not have the sensitivity to measure milliohms. We can measure the resistance of the motor winding by introducing another resistance component to a circuit.

Measuring Brushless Motor Winding Resistance However, we can determine the motor using inexpensive household tools. The wasted energy is converted to heat and this energy does not provide any form of work that contributes to our power output of the brushless motor in our RC vehicles. When power flowing through the wires are resisted due to the wire itself, it provides wasted energy. Every wire used in any application has a specific resistance per foot. Ohms are the unit of measurement for resistance in electricity. Well, it is the same for wires and it is ideal for a motors resistance to be zero ohms. This is all about split phase induction motor.Unfortunately nothing in life provides 100% efficiency.

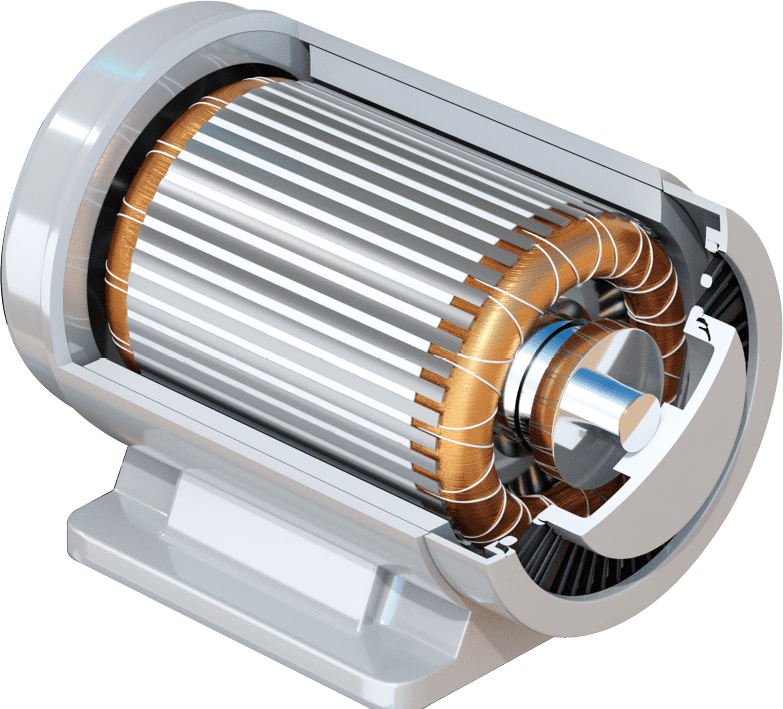

WHAT IS MOTOR WINDING FULL

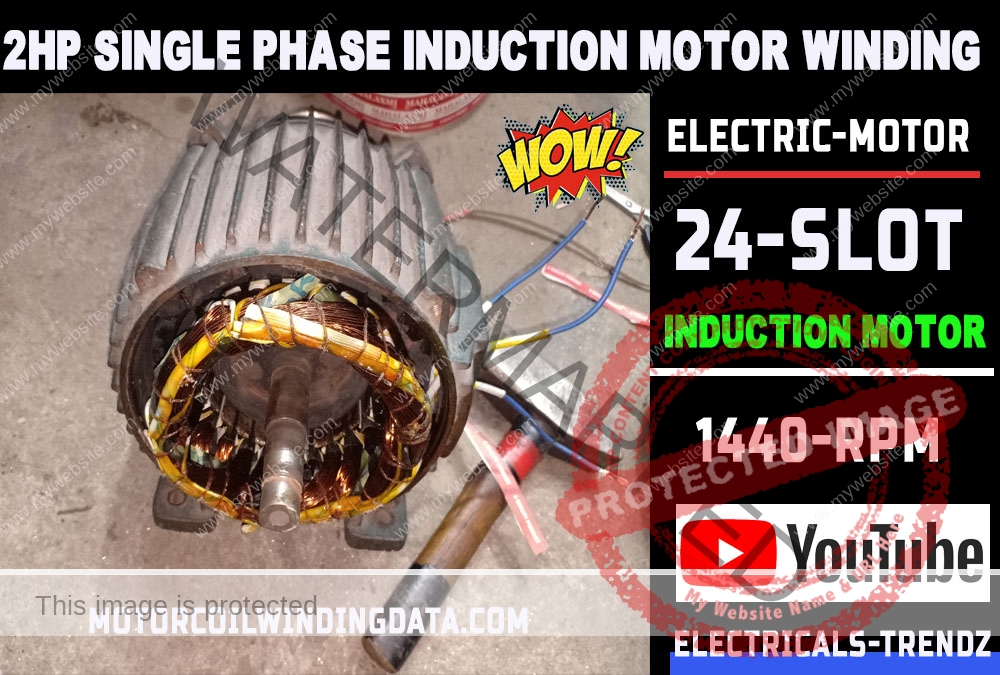

The starting current of the motor is high about 7 to 8 times the full load value. The maximum torque is about 2.5 times the full load torque at about 75% of the synchronous speed. The starting torque of the resistance start motor is about 1.5 times the full load torque. Here, n 0 is the point at which the centrifugal switch operates. The Torque Speed Characteristic of the Split Phase motor is shown below: This phase difference is enough to produce a rotating magnetic field. The time phase difference ϕ is not 90 degrees, but of the order of 30 degrees. Thus, there exists a time difference between the currents of the two windings. The current in the auxiliary winding I A is approximately in phase with the line voltage. The current in the main winding (I M) lags behind the supply voltage V almost by the 90-degree angle. The phasor diagram of the Split Phase Induction Motor is shown below: Therefore, the relay opens and disconnects the auxiliary winding from the supply, making the motor runs on the main winding only. Thus, the starting winding is in the circuit, and as the motor attains the predetermined speed, the current in the relay starts decreasing. In the starting, the heavy current flows in the circuit, and the contact of the relay gets closed.

WHAT IS MOTOR WINDING SERIES

If the motors are rated about 100 Watt or more, a centrifugal switch is used to disconnect the starting winding and for the smaller rating motors relay is used for the disconnecting of the winding.Ī relay is connected in series with the main winding. At the starting of the motor both the windings are connected in parallel.Īs soon as the motor reaches the speed of about 70 to 80 % of the synchronous speed the starting winding is disconnected automatically from the supply mains. Hence, the starting torque is small, of the order of 1.5 to 2 times the stated running torque. The current in the two windings is not equal as a result, the rotating field is not uniform. A resistor is connected in series with the auxiliary winding.

0 kommentar(er)

0 kommentar(er)